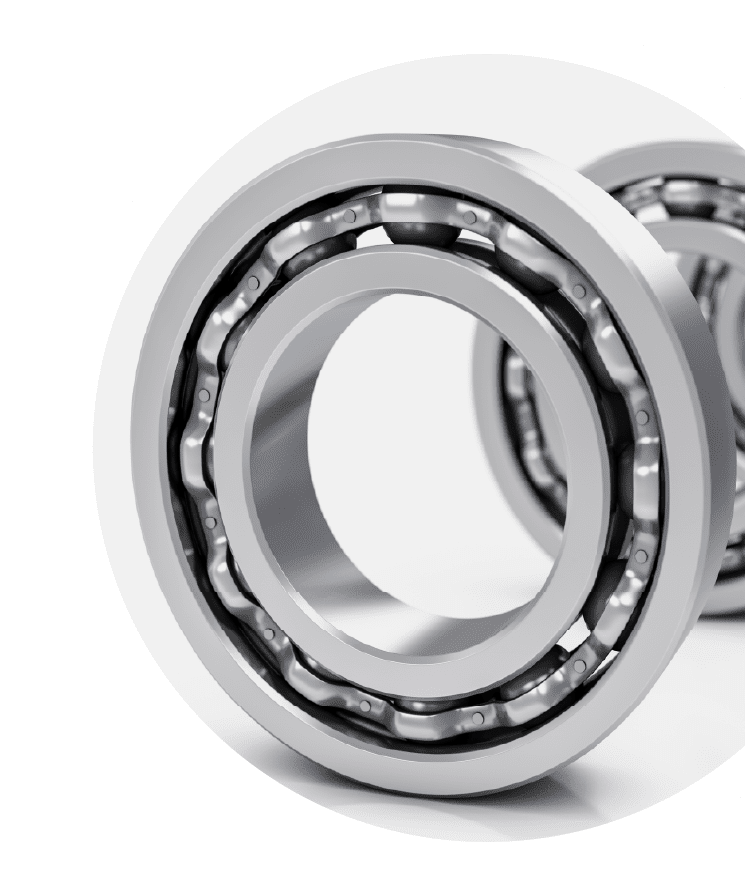

BEARING

SELECTED PRODUCTS

wheel bearing

Clutch bearing

Tensioner bearings

Needle bearings

Hub bearings

BEST CHOICE

FOR BEARING

The drive system transfers the power of the engine to the wheels and thus the vehicle moves. Several components work together to perform this central and complex task. Only high-quality parts should be used to achieve perfect harmony between the components.

Segal is your best choice for bearing kits and ensures that all parts are of the highest quality.

YOUR BENIFITS

Extensive Range of Products

With various type of SEGAL Bearings available, provides an all-makes range covering all popular vehicles on roads.

Clutch Release / Wheel Bearing

Tensioner Pulley, Timing Belt / Deflection/ Guide Pulley, V-Ribbed Belt

Needle Bearing / Hub Bearing

Guarantee and Commitment

Quality is SEGAL commitment.

Bearings quality exceeds essential basics.

With SEGAL Bearings you get maximum service intervals and optimal engine performance with long-life

SEGAL Bearings have Guarantee according type of products and OEM requirement

Highest Quality

All SEGAL Bearings undergo a rigorous quality control process to ensure they meet OE standards, reflecting the high-quality standards of the SEGAL Products.

SEGAL Bearings manufactures under certificate of,

ISO16949 / ISO14001

BE SAFE FROM SHAKING

WITH SEGAL BEARING

The system of drive shafts and bearings plays a vital role in transmitting the driving force of the gearbox to the wheels. At the same time, it has to flex and turn with the independent suspension system, enabling low rotational resistance and transferring axial and radial forces to the driven and steered wheels. Timely replacement of the bearing reduces the time the vehicle is in the workshop, makes the repair cost-effective and timely, and reduces user dissatisfaction..

HOW WE ENSURE QUALITY

Segal bearings are manufactured and engineered to the highest quality standards, ensuring they meet or exceed original equipment manufacturer specifications in fit, form, and performance. All materials used in wheel bearings, hubs, and wheel fastenings are checked for hardness, strength, and mechanical properties, as well as for accuracy of size and functionality. Additionally, a wheel bearing is run under a salt and mud spray test for numerous hours in order to evaluate lubrication and seals for durability. Wheel bearings are examined for abnormal sounds, cracks, damage, and any other abnormalities after reaching a test stage of over three times their typical product lifespan.