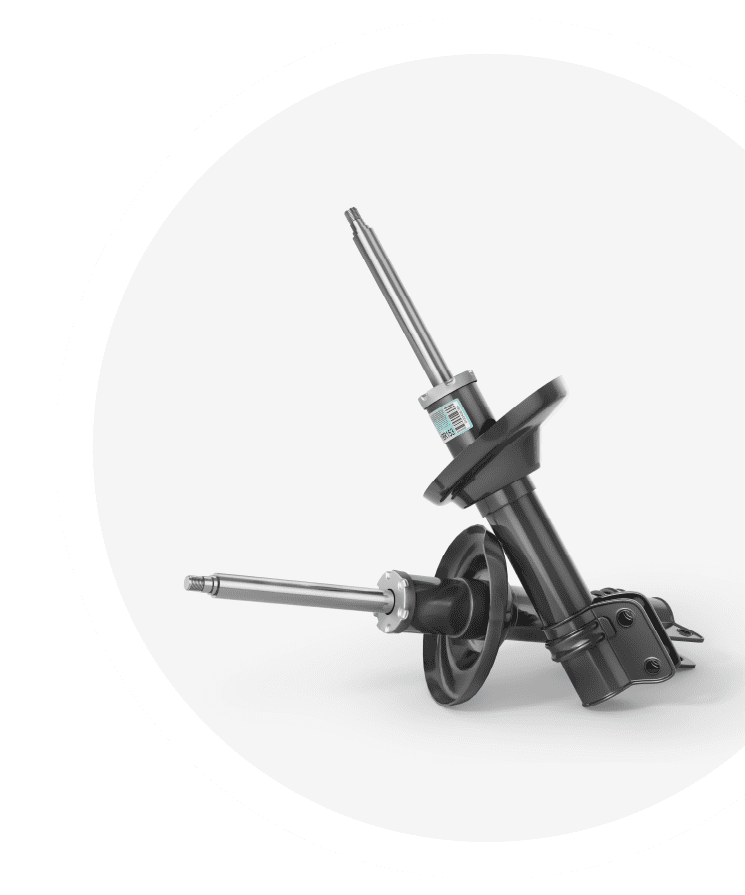

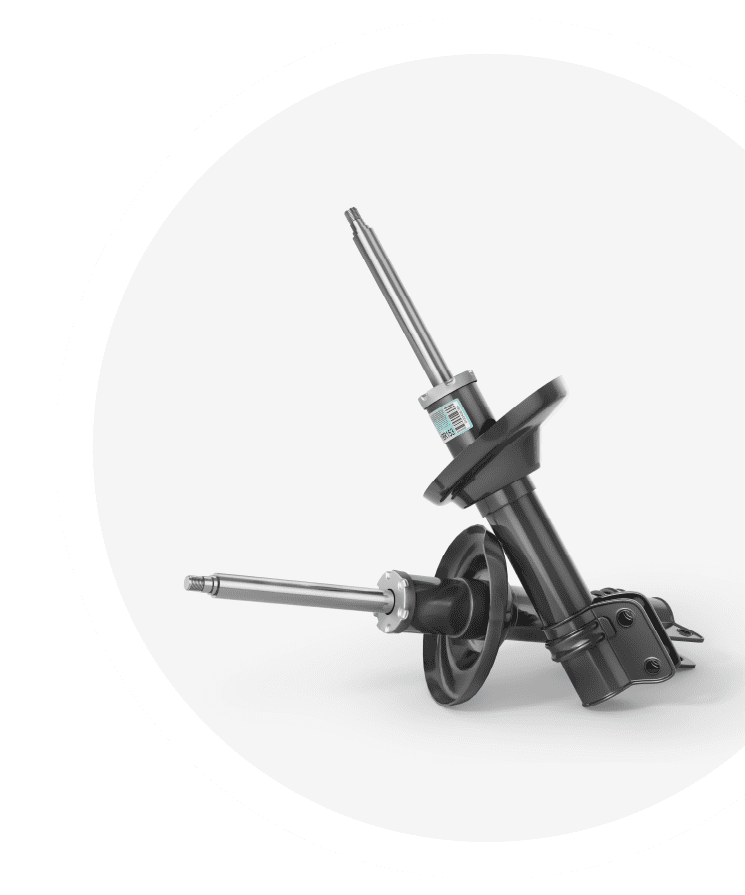

SHOCK- ABSORBER

SELECTED PRODUCTS

GAS PRESSURE

SHOCK- ABSORBER

OIL PRESSURE

SHOCK- ABSORBER

BEST CHOICE

FOR SHOCK ABSORBER

Driving without suspension on winding roads will be very uncomfortable and unsafe. To transfer the forces applied to the vehicle, it is necessary to establish a smooth connection between the vehicle and the road. Shock absorbers support the weight of the vehicle and allow it to move up and down smoothly to compensate for bumps and potholes in the road.

YOUR BENIFITS

Extensive Range of Products

With various type of SEGAL Shock Absorbers available, provides an all-makes range covering all popular vehicles on roads.

The products are: Shock Absorbers with GAS Presure

Shock Absorbers with OIL Presure

Guarantee and Commitment

Quality is SEGAL commitment.

Shock Absorbers quality exceeds essential basics.

With SEGAL Shock Absorbers you get maximum service intervals and optimal engine performance with long-life

SEGAL Shock Absorbers have Guarantee according type of products and OEM requirement

Highest Quality

All SEGAL Shock Absorbers undergo a rigorous quality control process to ensure they meet OE standards, reflecting the high-quality standards of the SEGAL Products.

SEGAL Shock Absorbers are manufactures under certificate of ISO16949

BEST CHOICE

FOR SHOCK ABSORBER

Shock absorbers are among the essential components of the car suspension system that reduce the oscillations of the springs and provide safety and comfort for the passengers. Worn and defective shock absorbers can also worsen the driving experience. Also, to ensure long-term durability, we use the best materials according to standards.

HOW WE ENSURE QUALITY

These tests aim to ensure the performance, resistance, and stability of the shock absorbers in different conditions so that the shock absorbers used in cars can function with high quality and optimally and be confirmed in terms of quality and safety.

Tensile Testing: Evaluation of tensile strength and deformation of compression and tension shock absorbers.

Compression Testing: Measuring the compression resistance of shock absorbers and their deformation under pressure.

Performance tests in different temperature conditions: To evaluate the performance of shock absorbers in hot and cold conditions.